Welcome to the official website of Fangyuan (Anhui) Intelligent Equipment Co., Ltd!

Telephone:+86-18905612563

Welcome to the official website of Fangyuan (Anhui) Intelligent Equipment Co., Ltd!

1.1 Overview of coal preparation plant

The Longquan Coal Preparation Plant of Taiyuan Coal Gasification Company is a large-scale dual-system with a design capacity of 5.00Mt/a that mainly produces coking coal and takes into account the production of thermal coal. The coarse slime system of the coal preparation plant accounts for 5% of the raw coal production rate and has an hourly processing capacity of 56.82t/h.

1.2 Sorting process

The coal preparation process in the design of the coal preparation plant is as follows: After the raw coal has been deslimed and screened (the desliming screen is 1mm), 50~1mm is separated by a desliming and pressureless three-product heavy-medium cyclone, 1~0.25mm The coarse coal slime is separated by TBS, and the -0.25mm fine coal slime is recovered by thickening and filter press as a medium coal product.

2.1 Separation and recovery process of coarse slime before technical transformation

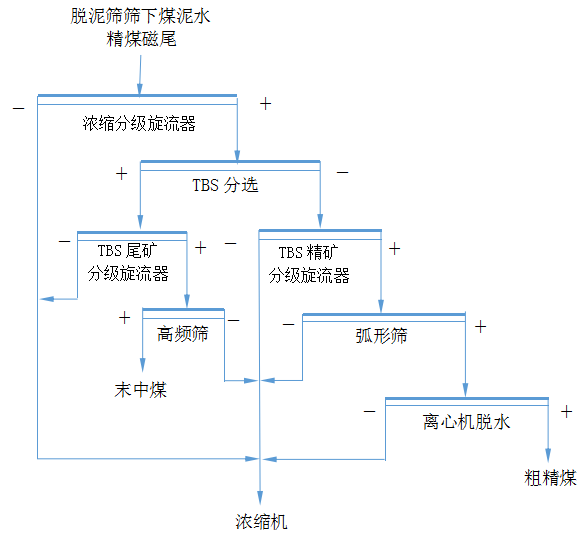

The separation and recovery process of coarse slime before the technical transformation of Longquan Coal Preparation Plant is: cyclone concentration + TBS separation + cyclone concentration + arc sieve desliming and dewatering + centrifuge dewatering. The specific process is shown in Figure 1.

Fig. 1 Process flow chart of coarse slime separation before technological transformation

2.2 There is a problem

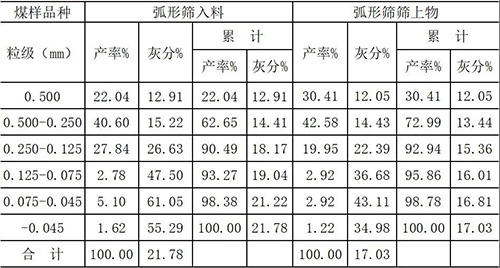

Table 1 shows the sieving test data of the curved sieve's input and over-the-screen material when the curved sieve was used to cut and categorize the TBS concentrate overflow before the technical transformation. From the comparison of the screening test data, it can be seen that the difference between the ash content of the incoming material and the sieve is less than 5%, which indicates that the screening efficiency of the arc sieve is low and the ash reduction effect is extremely poor.

Table 1 Screening test data of the arc sieve before the technological transformation

(2019.6.10)

Longquan Coal Preparation Plant has high ash content, serious gangue sludge, high internal ash, low concentrate yield, and large intermediate product content. Therefore, in actual production practice, the original design of the coarse slime separation and recovery process mainly has the following problems:

The original process adopts an arc-shaped screen with lower screening efficiency to cut coarse, sludge and dewater the overflow of TBS concentrate. Due to the serious muddy phenomenon of gangue in the raw coal and the high content of high-ash fine mud, it will inevitably cause: the curved screen contains a large amount of high-ash fine mud, resulting in high ash content of the coarse and clean coal; the curved screen uses stainless steel The slotted screen has a large screen gap and is easy to wear, which will cause a large amount of low-ash coarse slime to stray and lose coarse clean coal. At the same time, the screen needs to be replaced frequently.

3.1 Technological transformation plan

In order to improve the recovery rate of clean coal and economic benefits, Longquan Coal Preparation Plant combined with Anhui Fangyuan Plastic Co., Ltd. to transform the coarse slime separation system. After demonstration, it directly adopted Anhui Fangyuan Plastic Co., Ltd. to produce high screening efficiency, The FY-HVS-1500 laminated high-frequency screen with good desilting effect replaces the curved screen to efficiently and effectively cut the TBS overflow product and screen it.

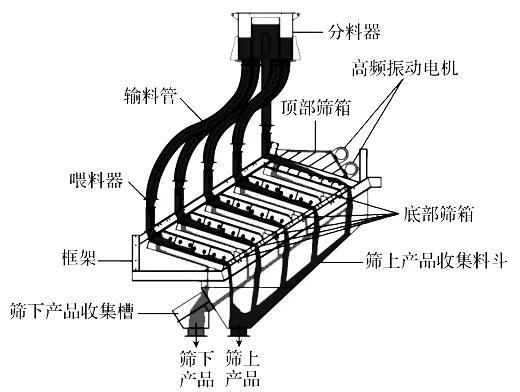

3.2 Structure and working principle of FY-HVS-1500 laminated high frequency screen

Fangyuan FY-HVS-1500 high-frequency stacked screen is a kind of mechanical equipment that uses the high-frequency vibration of the screen surface and the gravity of the material to achieve classification according to the particle size of the material. Its structure is mainly composed of a distributor, a feeder, and upper and lower screen frames. , High-frequency vibration motor, product collection hopper on the screen, product collection tank under the screen, frame and support platform. The working principle of the sieve machine is shown in Figure 2. Its main features and advantages are as follows.

图2 FY-HVS-1500型高频叠筛工作原理示意

Longquan Coal Preparation Plant has high ash content, serious gangue sludge, high internal ash, low concentrate yield, and large intermediate product content. Therefore, in actual production practice, the original design of the coarse slime separation and recovery process mainly has the following problems:

The original process adopts an arc-shaped screen with lower screening efficiency to cut coarse, sludge and dewater the overflow of TBS concentrate. Due to the serious muddy phenomenon of gangue in the raw coal and the high content of high-ash fine mud, it will inevitably cause: the curved screen contains a large amount of high-ash fine mud, resulting in high ash content of the coarse and clean coal; the curved screen uses stainless steel The slotted screen has a large screen gap and is easy to wear, which will cause a large amount of low-ash coarse slime to stray and lose coarse clean coal. At the same time, the screen needs to be replaced frequently.

3.1 Technological transformation plan

In order to improve the recovery rate of clean coal and economic benefits, Longquan Coal Preparation Plant combined with Anhui Fangyuan Plastic Co., Ltd. to transform the coarse slime separation system. After demonstration, it directly adopted Anhui Fangyuan Plastic Co., Ltd. to produce high screening efficiency, The FY-HVS-1500 laminated high-frequency screen with good desilting effect replaces the curved screen to efficiently and effectively cut the TBS overflow product and screen it.

3.2 Structure and working principle of FY-HVS-1500 laminated high frequency screen

Fangyuan FY-HVS-1500 high-frequency stacked screen is a kind of mechanical equipment that uses the high-frequency vibration of the screen surface and the gravity of the material to achieve classification according to the particle size of the material. Its structure is mainly composed of a distributor, a feeder, and upper and lower screen frames. , High-frequency vibration motor, product collection hopper on the screen, product collection tank under the screen, frame and support platform. The working principle of the sieve machine is shown in Figure 2. Its main features and advantages are as follows.

Figure 3 Site of stacked coal screening

Figure 4 Equipped with square round fiber reinforced polyurethane fine screen

The Longquan Coal Preparation Plant optimized the process of the coarse slime separation and classification system, and used high-efficiency and effective grading laminated high-frequency screens instead of arc screens to screen and classify the coarse slime products, reducing the amount of coarse slime products. The high ash and fine mud content makes the ash content of the final coarse clean coal product lower than the ash content required by the total clean coal. At the same time, the problem of rough running under the sieve is effectively solved. The coal preparation plant's field test showed that the ash content of the coal slurry under the sieve was increased from less than 55% to more than 65%, and the yield of the sieve was increased by about 5% compared with the arc sieve, and the economic benefit of the coal preparation plant was greatly improved.

|

Previous:Fangyuan Plastics Co., Ltd. joined the China Vibration Machinery Network Screening Pass member

Next:Anhui Fangyuan Plastic Technology Innovation "Screens" Out of Development |

Back to list |

Sales Contact